Our service on your location

Our service department is experienced and well trained. Our technicians have more than 10 years of experience in the industry. They provide expertise and support on site, and travel all over Europe.

Our activities - A total concept

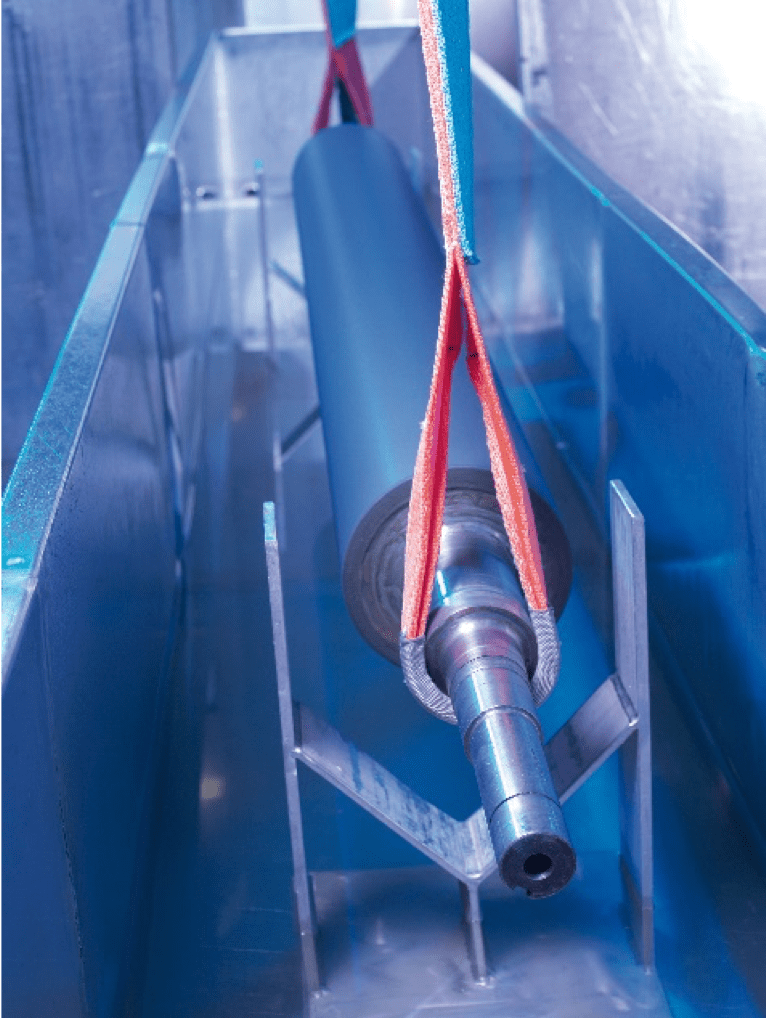

- Deepclean your Anilox rollers with different methods: Inline and offline deepcleaning: our brand new

- Provide aid when encounting printing problems

- Training of your staff to implement a good cleaning protocol

- Volume measurements: Provide a overview of the state of each printing united

- Install dosing systems to dilute the cleaners with water

- Automate your cleaning process

JetCleaning B.V.

Our service partner who offers all possibilities:

- Cleaning by means of chemicals

- Cleaning by means of blasting with sodium bicarbonate (NaHCO3)

- Cleaning by means of laser

Methods of measurements

Instruments to measure the state (volume) of your Anilox rollers:

- Ravol Liquid Volume Test

- Troika AniCAM

Support whenever you need it

Our service department is used in a versatile way. They deepclean on site. In this way, Flexoclean creates a base level of clean, close to the theoretical volume. Detailed reports are drawn up before and after cleaning, showing the difference and providing you with constant quality of your printing machines. With their expertise and know-how, they advise, implement and improve your total cleaning concept and knowledge.