Always the right solutions.

We make cleaning products for your printing demands.

The product we produce is safe, sustainable and can be disposed.

How we support you

The analysis

- Our knowledge and equipment

- Testing in our laboratory

- Tailor made products

The products

- Daily cleaning products

- Periodic cleaning products

- Supplies

The follow up

- Measurements

- Service: Deepcleaning

- Dosing systems

The Analysis

Our Chemical Engineers have the knowledge and the equipment.

Inks, varnishes and water are tested at our Technology Center to determine the best cleaner for you.

Advising the right cleaner for each situation.

The products

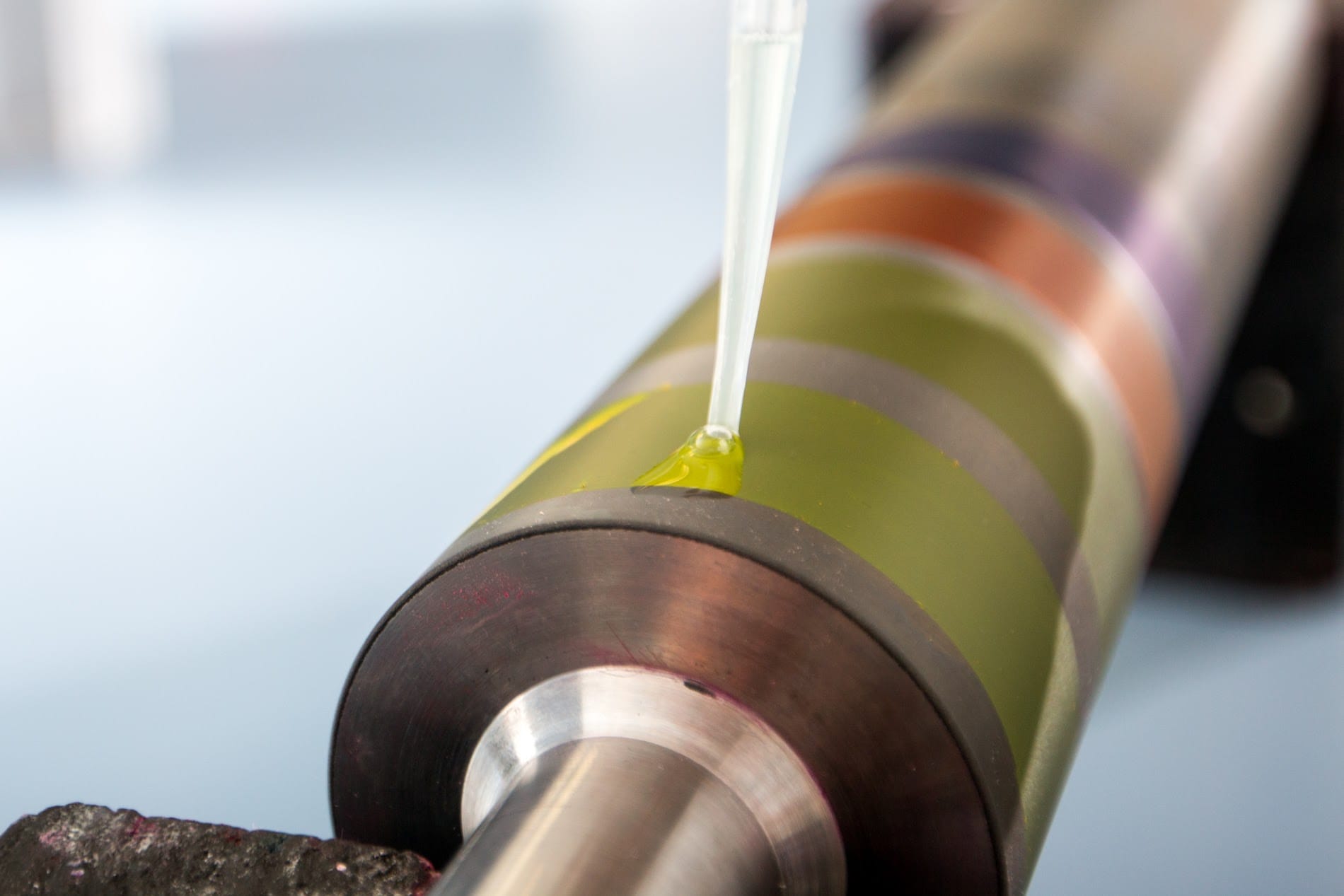

We offer a wide range of products which will help to maintain the condition and volume of your Anilox rolls.

- Cleaning products for daily maintenance of the Anilox rollers and Stereos.

- Periodic cleaning products for periodical maintenance of the Anilox rollers.

You can order our products in a 1 Kg bottle incl. triggersprayer, 5 or 20 Kg cans, 200 Kg drums or a 1000 Kg IBC.

The follow up

We use different types of equipment to measure the volumes to determine the state of your Anilox rollers.

Deepcleaning on location: Inline and/or Offline deepcleaning of your Anilox rollers.

Dosing systems: Automation of your cleaning process is to facilitate the work and maintain your printing quality.

Press here for more information

YOU ARE IN CONTROL

The importance of good cleaning, financial benefits and constant quality

With our products and services we make your results better

Discover now